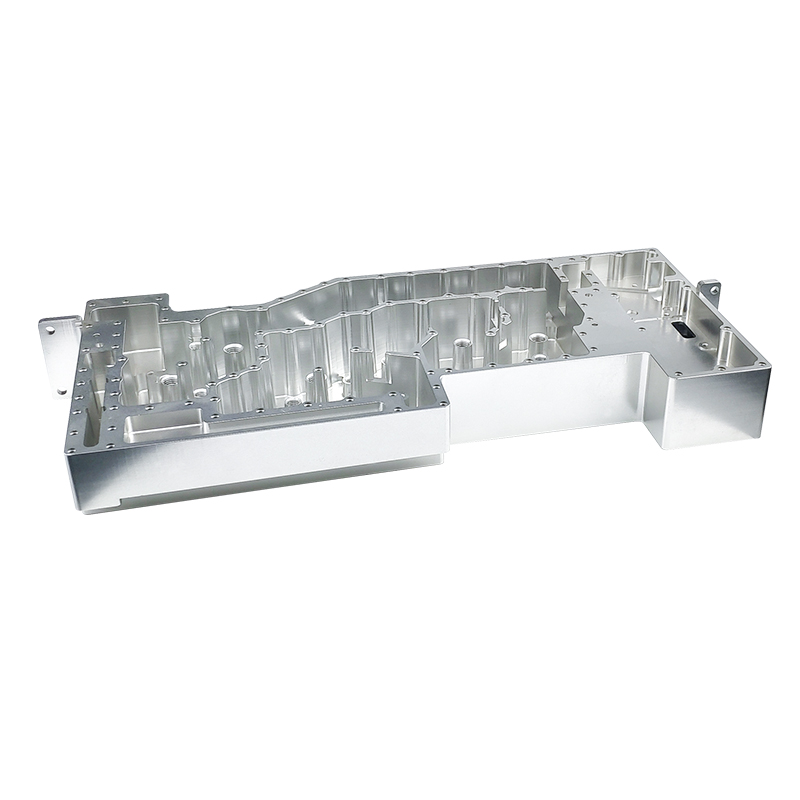

EHP has stalled 3 sets of advanced laser cutting machines, the Max power 3500KW brand AMADA and Min power 1000 KW. We are able to keep accurate blanking specification with the tolerance is +/-0.03mm, and the cutting speed is 7 meters per minute. At the R&D stage the demands is small quantities, most of the customers do not want to invest the NRE cost prior to the products certified, but it's high precision, we have AMADA laser cutting machine to meet the customer requirements. EHP is always seeking for advanced equipment to help our customers to lower their overall cost, shortening the delivery time and stabilizing the quality. Here the some advances from laser cutting machine:

- Good quality, Low labor cost

Laser cutting machine using laser non-contact processing characteristics, no damage to the workpiece, cutting products without extrusion deformation, processed products of good quality, no burr, no need for manual grinding, eliminate unnecessary processing procedures, optimize the labor intensity of workers.

- No tooling/mold investment, lowering production cost

Laser cutting machine can directly make all kinds of hardware work-piece without mold, no tooling/mold consumption, no need to repair and replace the mold, it can save the using of a large number of molds, save processing costs, reduce production costs, especially suitable for processing large size products.

- High precision, high production efficiency

Laser cutting process has the characteristics of precision, flexibility and efficiency, which it can effectively process a variety of complex parts, we just draw the cutting graphics, and upload into the control system, and set up the size of the cutting. Laser cutting machine helps to shorten the cycle of processing and manufacturing, effectively improve labor productivity.